FELIKS – Simulation Tool for Novel Battery Designs with Solid-State Electrolytes

Background and Problem

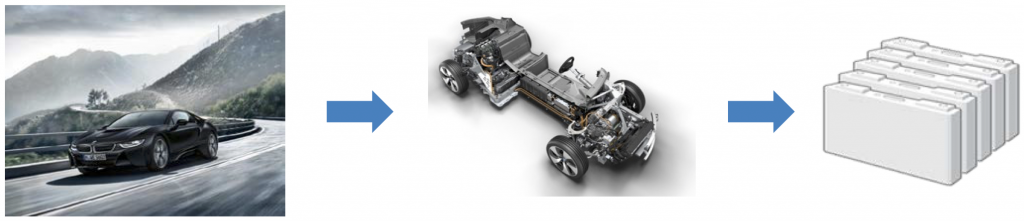

A turnaround in energy policy is currently taking place worldwide. In Germany, this turnaround is demanded particularly intensely in wide sections of politics and society. One of its key elements is the development and provision of efficient, economical, safe and sustainable energy storage systems such as rechargeable batteries. Two exemplary applications of rechargeable batteries are the compensation of temporal fluctuations in energy production by renewable energy sources, such as wind turbines and solar power plants, or the much-noticed field of electromobility, in which BMW is also particularly active as a worldwide operating automobile manufacturer, among others, by the production of vehicles of their sub-brand BMW i (see Fig. 1). A strong increase in the number of electrically powered vehicles is an objective that is currently being pursued intensively in Germany as well as in many other countries of the world. The German Government’s plan to aim at a number of one million electric and hybrid vehicles by the year 2020 is still in force. In France as well as Great Britain, according to recent political decisions, the sale of vehicles with internal combustion engines is to be banned from the year 2040 onwards. The batteries to be used in electrically powered vehicles are one of the key technologies for achieving the goals with respect to the electrification of transport.

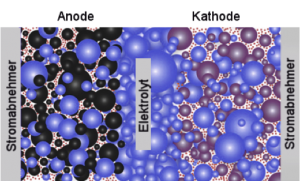

Lithium-ion batteries (LIBs) with liquid electrolytes represent the type of battery currently dominating the market for electric and hybrid vehicles. However, consumers still very often consider the range of vehicles with LIBs as insufficient. Meanwhile, solid-state batteries are considered by researchers to be potentially superior to LIBs in many respects. Both the liquid electrolyte used in modern LIBs and the separator, which nowadays mostly consists of polyethylene or polypropylene, are thereby replaced by a solid electrolyte. By using solid electrolytes, high-capacity materials may be integrated, which cannot be combined with liquid electrolytes. As a result, a substantial increase in energy density is enabled. Moreover, an increase in safety is achieved at the same time, since there are neither any inflammable liquid electrolytes whatsoever nor, in general, any liquid components potentially leaking from the cells, and the growth of so-called dendrites is reduced. Fig. 2 exhibits an exemplary variant of a solid-state cell including a so-called composite anode.

However, it is safe to assume that there is still a very long way to go until solid-state batteries will indeed be used on an industrial scale and may thus notably contribute to the aforementioned global transformation of energy systems. In general, there is no doubt that a lack of understanding regarding a large number of physical and electrochemical processes, respectively, in solid-state batteries still has to be conceded, counteracting a potential comprehensive development, production and use of solid-state batteries in this field of application.

Project Goal

Supported by the “Bayerische Forschungsstiftung” and headed by AdCo EngineeringGW GmbH, this project will make a decisive contribution to accelerating the use of solid-state batteries for the transformation of energy systems. On the one hand, computer-based simulations may support or accompany, respectively, experimental investigations. On the other hand, they allow for displaying and analyzing physical and chemical phenomena, which cannot (or merely with unjustifiable effort) be observed experimentally. Moreover, simulations offer completely new perspectives for design and development processes. Therefore, profound and predictive numerical simulations of the processes in solid-state batteries are decisive for goal-oriented and successful research and development aiming at insights of the physical and electrochemical processes and the design of novel, innovative concepts for solid-state batteries. However, due to the aforementioned complexity of the present electrochemistry-structure interaction problem, currently available commercial and “open-source” CAE software packages are not suitable for realizing such realistic and predictive computations. AdCo EngineeringGW GmbH develops as one of its key competences their own advanced simulation methods and uses them as the key to an improved understanding of this novel type of batteries in the present project.